NNL 690G

Power Up NNL 690G Printable Technical Data Sheet

Power Up NNL 690G has been developed to greatly enhance the lubricating properties of extreme pressure gear oils. Changing industry technology dictates improvements and demands specialization. Power Up has met this challenge head on.

Primary Benefits of NNL 690G:

- Reduced Friction

- Extremely High Film Strength

- Increased Energy Efficiency

- Improved Lubrication

- Reduced Dry Starts

- Increases Component Life and Equipment Availability.

- Reduced Operating Temperatures

- Reduced Maintenance Costs and Downtime

Applications for NNL 690G:

Recommended wherever EP (extreme pressure) oils are used at 3-5% rates. Including but not limited to:

- Gear Reducers

- Bearing Housings

- Chain Drives

- Standard Transmissions

- Bull Gears and Pinions

- Mud Pumps

- Differentials (except limited slip)

- Final Drives

- Low Ash Engines

- Cone and Jaw Crushers

- Rotary Tables

- Tube and Ball Mills

- Drop Boxes

Power Up NNL 690G is specially formulated for use in all types of mobile and industrial equipment where Extreme Pressure (EP) oils are called for (API GL-3 or greater). Specific applications include gear reducers, bearing housings, differentials (except limited slip), cone and jaw crushers, pulverizing equipment, final drives, conveyor drive gear boxes, standard transmissions, drop boxes, rotary tables, tube and ball mills, chain drives, mud pumps, bull gear and pinion sets, etc.

The primary benefit of NNL 690G is to reduce the friction caused by asperity (metal to metal) contact in the boundary lubrication regime. It is designed for lubricated systems which call for extreme pressure (EP) oils and engines requiring low ash-content oils.

Secondary Benefits of NNL 690G:

- Reduces ultrasonic wear noise which relates directly to component wear

- Reduces dry start-ups

- Lowers operating temperatures and slows oil degradation.

- Decreases wear in cold temperature applications (conventional EP additives are very dependent upon temperature to chemically react with the wear surfaces). The high film strength protection provided by NNL 690G is less dependent on temperature

- Reduces fuel and/or electrical amperage consumption in gearbox or reducer applications

- Improves filtration efficiency by reducing the generation of large wear particles

- Non toxic

Technical Presentation on Power Up NNL 690G:

{slideboom}[slideboom id=403544]{/slideboom}

Product Application:

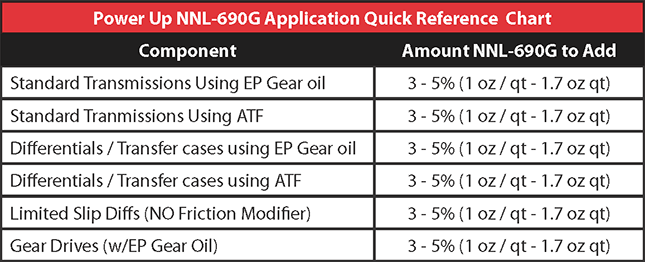

NNL 690G is intended for use in all types of mobile and industrial equipment where EP oils are used. NNL 690G should be applied with each oil change at 5% of the gearbox capacity. With gear oils heavier than ISO 320, NNL 690G should be used at 3-5%. In internal combustion engine crankcases using low ash or ashless oils, NNL 690G should be used at 3% of the oil volume with each change. It is also suitable for use in automatic transmissions at an application rate of 1%, in power shift transmissions at 3%, and in circulating systems at 3% or 5%, depending on the severity of service. NNL 690G is compatible with mineral based oils and with synthetic oils based on polyalphaolefins and diesters. At recommended application rates, it will not effect typical gear or engine oil viscosity ratings or seal materials.

Available in the following convenient sizes:

150 ml (5 oz.) Bottle

1 Liter (35 oz.) Bottle

1 Gallon (128 oz.) Jug

20 Liter (5.5 Gallon / 700 oz.) Pail

205 Liter (56.05 Gallon / 7,175 oz.) Drum