NNL 690

Power Up NNL 690 Printable Technical Data Sheet

Power Up NNL 690 is a unique boundary lubricant which is specifically formulated to solve many of today’s tribological problems in high pressure boundary conditions where metal to metal contact is inevitable. NNL 690 works by forming a wear reducing, protective film which is capable of withstanding extreme pressures as high as 200,000 lbs per sq. inch. NNL 690 provides critical engine parts, such as the ring zone, cam lobes and turbocharger, with boundary lubrication protection far exceeding that of conventional oils. NNL 690 is a carefully balanced, complete additive package which contains anti-wear and extreme pressure additives, detergent/dispersants, viscosity index improvers, corrosion inhibitors and acid neutralizers.

Primary Benefits of NNL 690:

- Strong film affinity maintains lubrication at start-up.

- By reducing the generation of large wear particles, the efficiency of the oil filter is improved.

- High base number helps neutralize acids that cause corrosion.

- Reduces friction and metal to metal contact in high load areas of the engine.

- Extends equipment life and increases equipment availability.

- Has a powerful detergent which cleans and suspends sludge and varnish.

NNL 690 is specifically designed for use in engines calling for medium to high ash oils (1.0% or more) and is suitable for use in most other lubricated equipment using non-E.P. oils. NNL 690 provides engines with exceptional anti-wear protection and also contains a superb detergent/dispersant package, viscosity index improvers and excellent anti-corrosion additives. NNL 690 is a balanced additive package that provides complete lubrication when used with good quality mineral based and synthetic oils.

The primary benefit of NNL 690 is friction reduction at the boundary lubrication regime (metal to metal contact). This includes the ring zone, turbocharger and camshaft lobe areas in engines, and the pump, cylinder rods and valves in hydraulics.

Secondary Benefits of NNL 690:

- Reduces ultrasonic wear noise which relates directly to component wear.

- Helps prevent sludge and varnish formation.

- Lowers operating temperatures by reducing friction.

- Provides an improved seal around the ring zone area, improving combustion efficiency and reducing smoke opacity and blow-by.

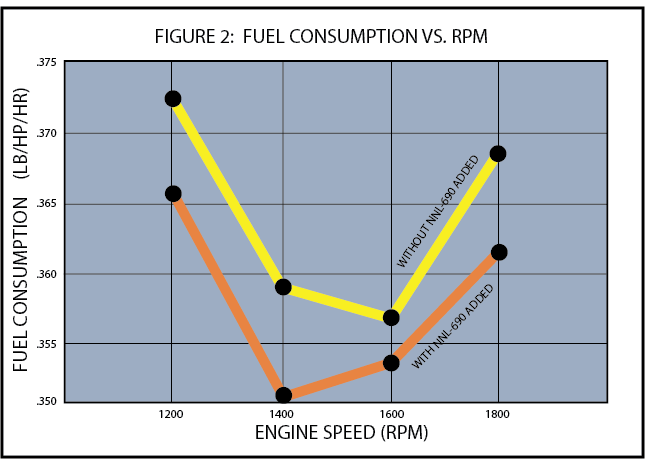

- Reduces fuel and/or electrical power consumption.

- Improves filtration efficiency by reducing the generation of large wear particles.

- Extends equipment life and increases equipment availability.

- Reduces friction and lowers temperatures in critical bearing and ring zones.

Decreasing operating expenses, longer machinery life and remarkable fuel conservation are some of the benefits enjoyed by using NNL 690. This means that your vehicles and equipment will last longer and operate more efficiently, while saving you money. NNL 690 reduces metal to metal contact like no other product, cleans, protects and reduces operating temperatures.

With over 80 years of fluid power engineering experience, testing by Fluid Engineering Services Inc., in Stillwater, Oklahoma concluded that “test results reveal that the Power Up NNL-690 has an SLI (Service Life Improvement) of 2.5 over regular oils alone.” This means when NNL 690 was tested with conventional oils it increased the component life at least 2 1/2 times longer than oils that were not treated.

Our Tests Prove it! Check for Yourself:

- High Film Strength

- Better Protection at High Temperatures

- Protects Against Dry Start Up Wear

- Improves Oil Flow in Cold Weather

- Keeps Parts Clean and Moving Freely

- Reduced Fuel Consumption

- Protects Against Water and Antifreeze Contamination and Diesel Dilution

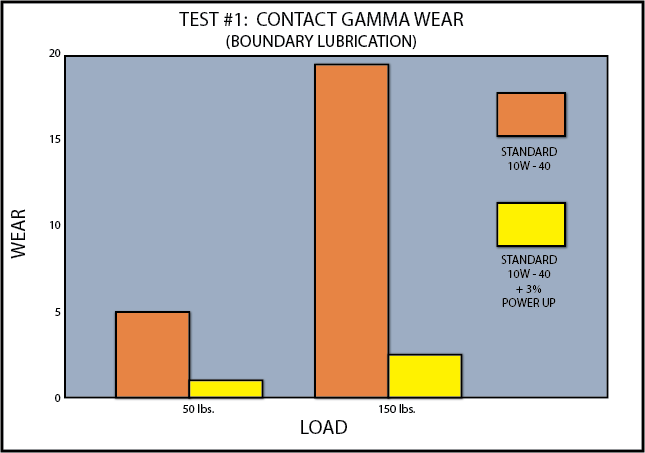

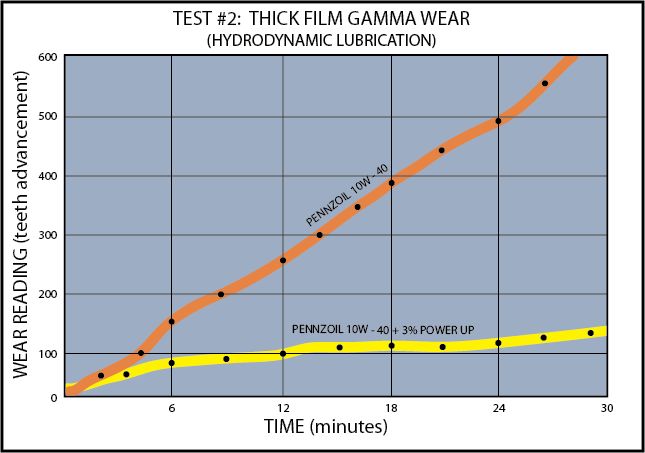

In two test pairs, after the addition of Power Up NNL 690, under heavily loaded conditions, the amount of wear was reduced between 39% and 87% depending on the load. An average of 18.9% wear reduction was recorded after the addition of Power Up NNL 690 even under hydrodynamic lubrication conditions.

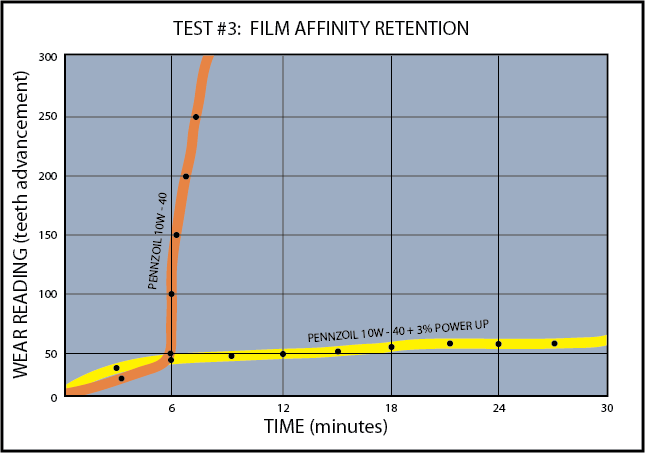

Fluid film retention performance is improved as much as 300% by using Power Up NNL 690 as demonstrated when oil supply is removed.

Extreme Lubrication Protection:

In independent Contact Gamma wear tests, NNL 690 significantly reduced the amount of wear generated when an engine oil alone was used. Calculated estimates based on wear reduction (up to 86.9%) suggest that the use of NNL 690 can extend equipment life over 7 times by reducing typical friction losses that occur in normal day to day operations.

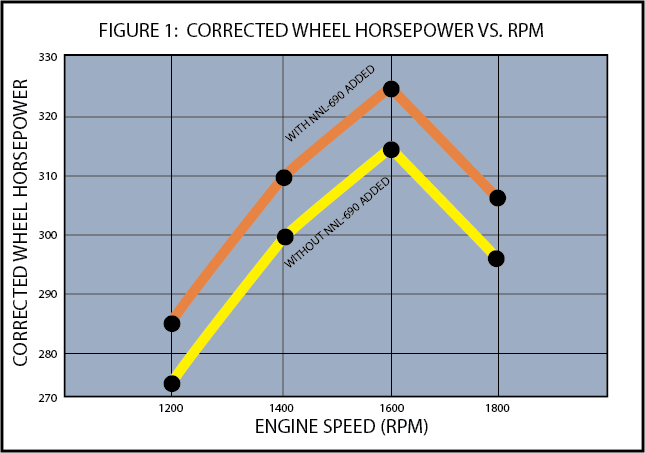

A series of dynamometer and ultrasonic noise tests were carried out by an independent consultant to determine the effect of NNL 690 on a diesel highway tractor engine. The application of 3% (by volume) NNL 690 increased the horsepower and torque, while reducing fuel consumption, ultrasonic wear noise and emissions. Some of the computer controlled and corrected dynamometer results are given in Figures 1 and 2.

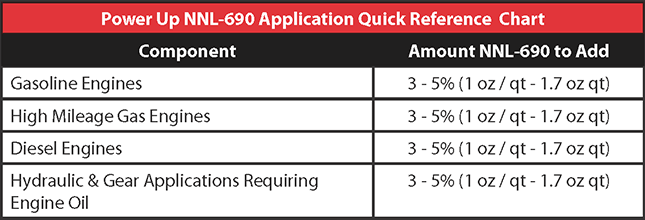

Product Application:

NNL 690 is intended for use in internal combustion engine crankcases at 3% of the oil volume, each time the oil is changed. It is also suitable for use in automatic transmissions at an application rate of 1%, in power shift transmissions at 3%, and in circulating systems at 3% or 5%, depending on the severity of service. NNL 690 is compatible with mineral based and synthetic oils based on polyalphaolefins and diesters. At recommended application rates, engine oil viscosity ratings and typical engine seal materials remain unchanged.

Technical Presentation on Power Up NNL 690:

{slideboom}[slideboom id=400842]{/slideboom}

Available in the following convenient sizes:

150 ml (5 oz.) Bottle

1 Liter (35 oz.) Bottle

1 Gallon (128 oz.) Jug

20 Liter (5.5 Gallon / 700 oz.) Pail

205 Liter (56.05 Gallon / 7,175 oz.) Drum